Gate 5 transforms material thought of as “waste” into safe and usable products, and drives positive public health, environmental, and climate impacts.

For too long, we have thought of sewage as waste and disposed of it accordingly, rather than unlocking its full value.

Gate 5’s widely scalable process eliminates many of the challenges and expenses of current sewage processes, while transforming sewage into safe and valuable products (renewable energy, clean water and building materials).

Further, Gate 5 eliminates climate-harming methane and diesel pollution, and destroys pharmaceuticals, microplastics and other troublesome compounds that todays processes do not.

Beyond wastewater, Gate 5’s process is adaptable to the agribusiness/animal waste and food processing/waste sectors.

“We need to understand wastewater as raw material ore with impurities. If we remove the impurities, we can extract energy, water and materials from this valuable substance.”

Dr. Sebastien Tilmans

Stanford University, PhD

Process

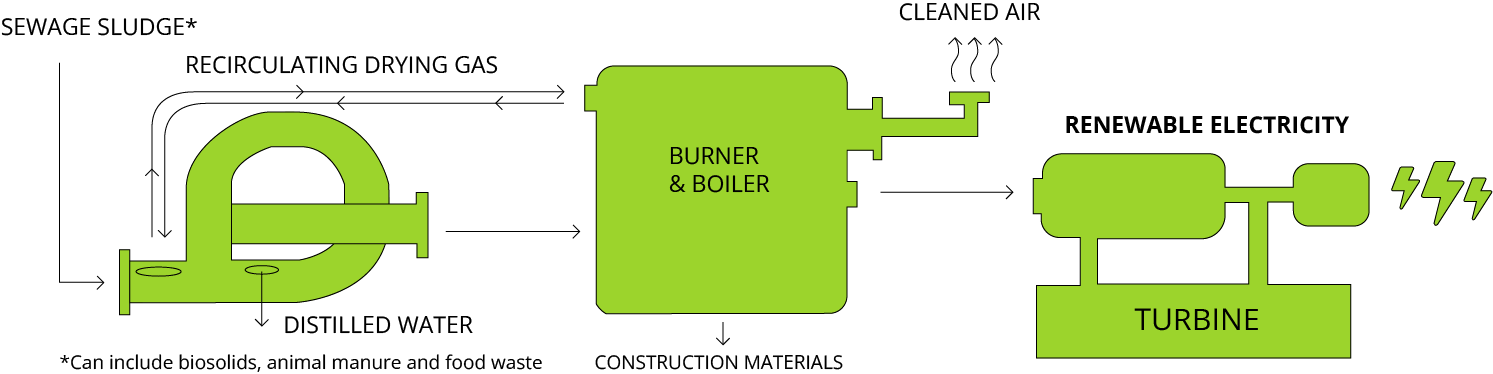

Gate 5’s technology – patented in the U.S. and seven other nations – integrates proven components to cost-efficiently transform sewage and other organic material sludge into 100% safe and usable assets, including renewable electricity.

Gate 5’s technology – patented in the U.S. and seven other nations – integrates proven components to cost-efficiently transform sludge into 100% safe and usable assets, including renewable electricity.

A pound of sewage sludge contains an average of

0

BTUs

the same as an average pound of coal

A pound of sewage sludge contains an average of

0

BTUs

the same as an average pound of coal

Gate 5 recognizes that what has been treated as “waste” is in fact a valuable asset, and our process will unlock its potential worldwide.

Gate 5 recognizes that what has been treated as “waste” is in fact a valuable asset, and our process will unlock its potential worldwide.

Today California, Tomorrow the World

Sewage contains as much energy as coal, but burns cleaner, and is not a fossil fuel

Gate 5’s impact in California will be massive – and we will scale globally.

If We Treat Sludge as a Burden

Annually, leave our children in California with:

-

487 thousand tons of methane in the atmosphere

-

2,378 gigawatts of electricity used

-

507 tons of air pollution from hauling

-

Millions in costs to manage sludge

-

Diesel fuel: $34 million

-

Hauling: $99 million

-

Plant operating costs: $462 million

-

Sludge as a Renewable Energy Source

Make a positive impact towards sustainability…

-

Eliminate 700,000 tons of methane annually from California wastewater plants

-

Eliminate 500 tons of vehicular pollution annually from hauling sludge

-

Eliminate the need for 2,400 gigawatts of fossil fuel energy, while producing 800 gigawatts of renewable power at California wastewater plants

-

…and destroy microplastics, pharmaceuticals and contaminants of concern

Starting in our home state of California, Gate 5’s impact will be massive – and will scale globally.

Gate 5 Solution and Benefits

Our sustainable and scalable thermal process will turn wastewater into 100% safe and usable products. Just in California, Gate 5 can …

Global Impact

According to the U.N., 6 billion people on the planet completely lack sanitation – Gate 5 will change this

Those completely lacking sanitation suffer from disease, malnutrition, polluted environments and shortened lifespans.

Gate 5’s straightforward and scalable solution can be deployed globally to villages and urban areas. Being a thermal process, it can be installed and operated at a much lower cost than current approaches, eliminating contaminants of concern and greenhouse gases from the environment, improving quality of life, providing renewable energy, and creating a more sustainable future.

“Conventional wastewater treatment is an approach that, for the wealthiest segments of the world, has enabled major advances in protection of public health and the environment. For the rest of the world, it is an expensive, unattainable pipe dream.”

Dr. Sebastien Tilmans

Stanford University, PhD

The Present

The wastewater industry has been content with incremental improvements to long-used methods and not given much attention to innovation. But today’s concerns over climate impacts, public health and the environment are driving regulations that will require improvements beyond the capabilities of long used equipment and processes.

The Future

Gate 5 has reimagined wastewater treatment – we see sewage sludge and other wastes as resources.

Gate 5’s thermal process is powered by transforming waste into surplus electricity – and in the process, destroying of the contaminants that are the focus of new regulations.

Questions? Contact Us